Research

Crystallization and Biocatalysis |

||

|

|

|

|

Compartmentalization and Biocatalysis |

||

|

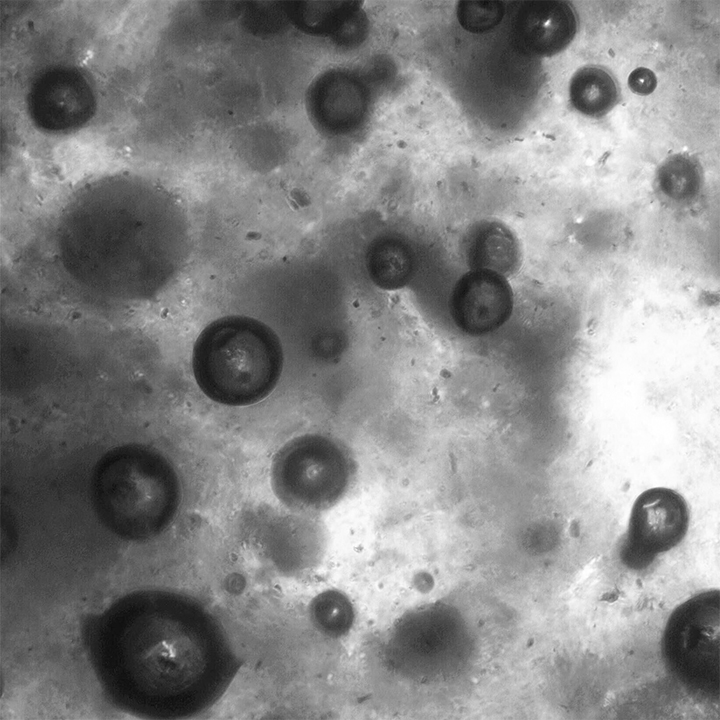

Compartmentalization is a powerful concept to entrap biocatalysts into or behind (membrane) materials to generate contrary reaction conditions for chemical or chemo-/biocatalytic reactions. The reactants typically pass through the semi-permeable materials to connect complex multicatalytic reaction networks. Herein especially enzyme-catalyzed reactions with incompatible reaction requirements can be combined and used for synthetic purposes. In this concept we investigate UV-curing compartmentalization for the encapsulation of biocatalytic reaction systems. UV-curing provides at ambient temperatures a very high dispersion of the encapsulated aqueous domains, which facilitates a fast exchange of reactants and thus high catalytic performance. Both (partly) purified enzyme preparations and whole cell biocatalysts are used in such compartments for the synthesis of valuable products and intermediates. |

|

Thermomorphic Solvent Systems and Biocatalysis |

||

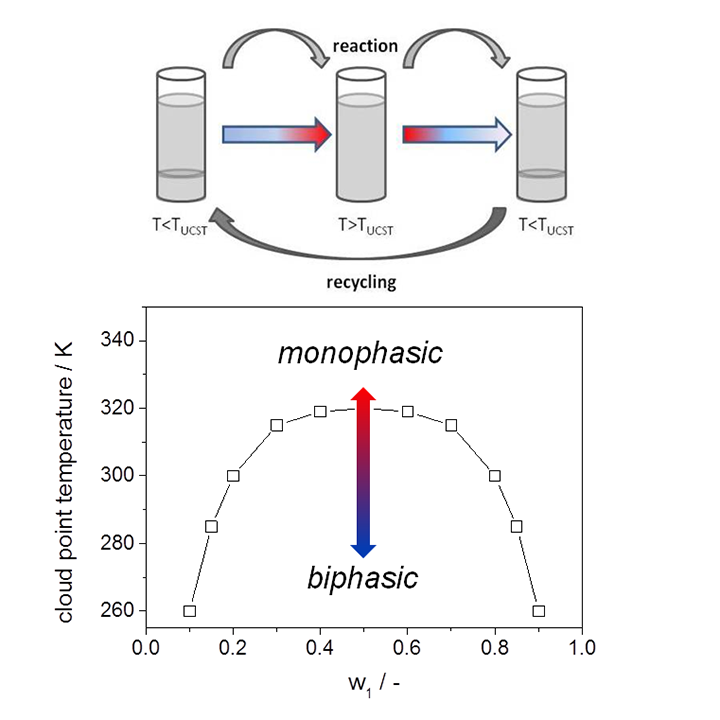

Thermomorphic solvent systems are specific solvent mixtures that exhibit a temperature-dependent miscibility gap, which allows the utilization of a reversible macroscopic phase change between mono- and multiphasic conditions. For systems with upper critical solution temperature-type phase behavior (UCST), monophasic reaction conditions at higher temperatures and an easy recycling of the biocatalyst after phase separation at lower temperatures can be achieved. We study the liquid liquid phase equilibria of such ionic liquid/buffer/organic solvent-mixtures with UCST-type behavior and evaluate their usability for biocatalytic reactions. This reaction concept provides, in comparison to classical solvent systems, an improved biocatalytic behavior in combination with a simplified downstream processing approach. Here especially imidazolium- and cholinium-based ionic liquids show good to excellent applicabilities in such reaction systems. |

|

|